Mood:

Topic: Single Crystal Blade

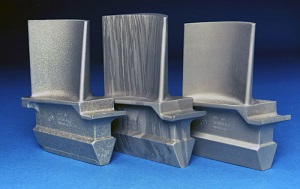

Single crystal blade is a casting blade with only one directional crystalline grain, which eliminates the lateral grain boundary sensitive to cavitation and cracks and makes all grain boundaries parallel to the stress axis, thus improving the performance of the alloy. Single crystal turbine blades have been crucial to the development of jet engines over the past 60 years and have been an important technology for the aerospace industry.

The main material used in aero-engines is nickel-based high-temperature alloy. Normally, nickel can bear the high temperature of 1000℃ or so, but it is easy to oxidation and deformation at high temperature. Therefore, other refractory metal elements need to be added to keep the nickel base high-temperature alloy blades strong and resistant to oxidation at extreme temperatures, which means that the nickel alloy blade material closest to the engine combustion chamber must be able to operate at temperatures well above its melting point and must be cooled to 80 to 90 percent of its melting temperature. As a result, the alloy material used in the engine blade is the key factor to determine the performance and life of an aero engine.

The development of single crystal blades dates back to the 1950s when engineers in the United States went from concept to manufacturing for about 10 years. In 1966, American engineers created directional solidified columnar grain turbine blades, which are the first step toward single-crystal blades, and the nickel-based alloy contains carbon, boron, and zirconium.

By the 1970s, American engineers had continued to build on the first generation of improvements to make a new alloy, which is the single-crystal castings called SX alloys that are still in service today. The SX alloy replaced carbon, boron, and zirconium with the new monocrystalline formula, which roughly includes nickel (59%), cobalt (10%), tantalum (9%), aluminum (6%), tungsten (6%) and other elements (10%). Among other elements, the most important material is rhenium (3%), which allows the final alloy to withstand higher temperatures before weakening and melting.

The single crystal is a superalloy grown from a single crystal in a vacuum casting furnace. It can improve the efficiency and service life of a turbine while giving it unparalleled resistance to high-temperature creep and fatigue. In a jet engine, the relative life of a single crystal turbine blade has been shown to be up to nine times higher in terms of creep strength and heat resistance fatigue than that of an equiaxial crystal blade, and the corrosion resistance of the relative life more than three times.

Stanford Advanced Materials supplies high-quality metal products to meet our customers' R&D and production needs. Please visit http://www.samaterials.com for more information.