Mood:

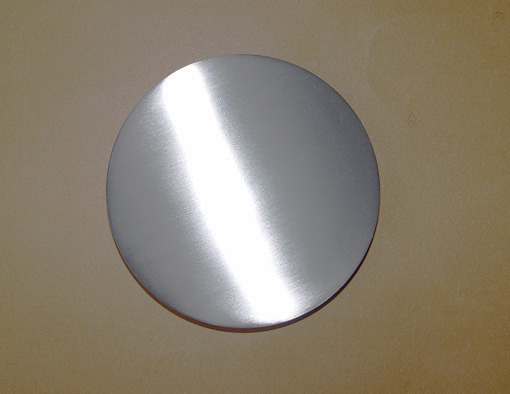

Topic: Tungsten Alloys Disc

Tungsten alloys are alloys based on tungsten with other elements added, while tungsten alloy disc is made of tungsten-molybdenum alloy or tungsten thorium alloy or rare earth tungsten alloy or tungsten-rhenium alloy. Tungsten alloy disc is easy to process and has better performance than that of molybdenum disc, so it is commonly used as the substrate of electric semiconductor devices and electric vacuum devices.

According to the material, tungsten alloy disc can be divided into the hard alloy, high specific gravity alloy, metal perspiration material, contact material, electron and electric light source material, etc. It has many excellent properties, such as high density, high hardness, high strength, high melting point, heat conduction, electric conduction and electron emission, which is widely used in aerospace, aviation, military, oil drilling, electrical instrumentation, medicine and other industries. The application of tungsten alloy disc in the mechanical industry is listed below.

It can be used to process ionic injection parts, make electric light sources and electric vacuum parts, and produce cover plates in a sapphire crystal growth furnace, and it can also be used in the hair tropics, connectors in the vacuum furnace, as well as plasma coating sputtering target materials and tungsten boat products;.

It is suitable for making cast iron roll and high nickel chrome roll dressing and forming tool;

It is applicable to manufacture discharge plate, punch die, punch die, punch die, electronic progressive die and other stamping dies;

It can be used as tungsten steel liner;

It is used to make wear-resistant parts;

It can be used for processing high-density fiberboard, density board tungsten steel liner;

It has a high cost performance.

Besides that, hard alloy disc is used for cutting hard materials such as copper parts and stainless steel parts. The monolithic cemented carbide disc cutter is suitable for cutting or grooving of ordinary steel, alloy steel, quenched steel, copper, aluminum, stainless steel, titanium alloy and other metal materials and electronic printed circuit board, cement stone tile, wall tile, paper, adhesive paper, rubber, leather and other non-metallic materials.

Stanford Advanced Materials supplies high-quality tungsten products to meet our customers' R&D and production needs. Please visit http://www.samaterials.com for more information.